How 3D Printing Is Driving Innovation In Manufacturing

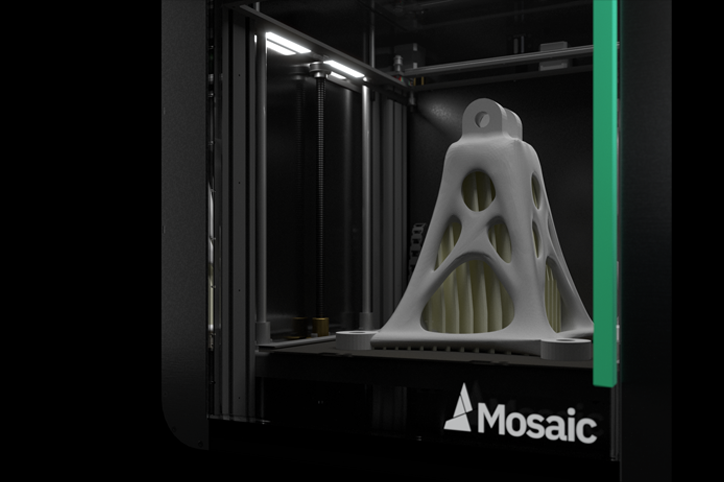

Mosaic Manufacturing’s Industrial 3D Printer

Source: https://www.mosaicmfg.com/

Have you harnessed the capabilities of 3D printing yet? Or are you still relying on conventional machining and casting processes?

3D printing is just one of the many new technologies that are innovating the way manufacturing organizations operate. If you’ve put off adopting this technology so far, it won’t be long before your competitors outpace you.

What Advantages Does 3D Printing Offer Manufacturers Like You?

Lower Labor Costs: The conventional manufacturing machinery you currently use requires a number of different people to operate a number of different machines. 3D printing technology simplifies and consolidates this arrangement, requiring only an operator to start the machine after a design has been uploaded.

Lower Manufacturing Costs: In a traditional manufacturing environment, you need to pay an initial setup cost, then produce and sell enough of the product to justify that investment. As mentioned above, doing so requires you to pay a team of machining specialists to operate the machinery involved. It’s an expensive process that only pays off eventually.

With 3D printing, you only pay for the filament material. The printer can be used to produce a range of different parts, meaning there are no additional setup costs or a need for massive initial investments. Furthermore, errors and wasted materials are not nearly as common or expensive.

e-Nable France uses 3D printers to develop custom prosthetics at a low cost.

Source: https://www.mosaicmfg.com/blogs/stories/enable-case-study

Customization and One-off Designs: This makes it far easier for manufacturers to engage in custom and iterative design projects for clients, which would be inordinately expensive with traditional production methods.

Develop Composite Products With Stronger Materials: 3D printing will allow your firm to use high-strength materials in production (various metals and even carbon fibre), and implement multi-material printing processes that can combine different mediums, such as metals coated in plastics and alloys.

Reduced Timelines: Unlike conventional machinery, 3D printers do not need to be retooled between the production of different parts. This drastically cuts down the turnover from one order to the next.

Optimized Concept & Design Projects: The speed at which 3D printers can produce new iterations of a given design makes it far easier to test designs, develop concepts, and improve them one generation after another.

Boeing’s “free form additive manufacturing” provides a more efficient mechanical design.

Source: https://www.boeing.com/features/innovation-quarterly/nov2017/feature-thought-leadership-3d-printing.page

Consider Boeing’s use of “free form additive manufacturing”, which took advantage of 3D printing’s fast and adaptable capabilities to rethink the way they produce and design satellites. Thanks to the advantages offered by 3D printing, they were able to vastly simplify their entire approach to design and manufacturing.

Remove Limitations: Whereas traditional machinery has certain limitations in terms of the geometries available, 3D printers offer a far greater range of possibilities limited only by the extent of the design you choose to upload.

Future Capabilities and Decreasing Costs: As an emergent technology, the cost of some filament material used by 3D printing may be high right now, but new alternatives are being developed and tested as you read this. Just like other business technologies, as it gains more and more popularity, both printers and printing material will continue to develop and become less expensive and more accessible over time.

Reduce Waste: 3D printing produces far less material waste than traditional manufacturing methods like injection molding. Printers only require material that passes through the extruder, vastly reducing material wasted in the production process.

Increase Warehousing Space: The precise nature and economy of scale offered by 3D painting makes it far easier for manufacturers to produce the exact amount of parts and products they need. That means you won’t need to lease nearly as much storage space for inventory that will sit on shelves until it’s sold years later.

Need Expert Assistance Harnessing 3D Printing? happier IT Is Here To Help

Every organization encounters challenges with adopting new technology and embracing the future. However, modernizing your manufacturing process doesn't have to be a massive restructuring of the way you do business. We can help you implement and adopt new technologies in a simplified, step-by-step process that works for you.

Connect with one of our industrial IT experts today and let happier IT help you discover how to harness new technologies like 3D printing.

Call us at 1-888-974-2779 or schedule a Free IT Assessment today!